Contact Information

Tel:+86 15101145231

E-mail:1085557209@qq.com

Add: Economic Development Zone, Shunping County, Baoding City, Hebei Province (North Park)

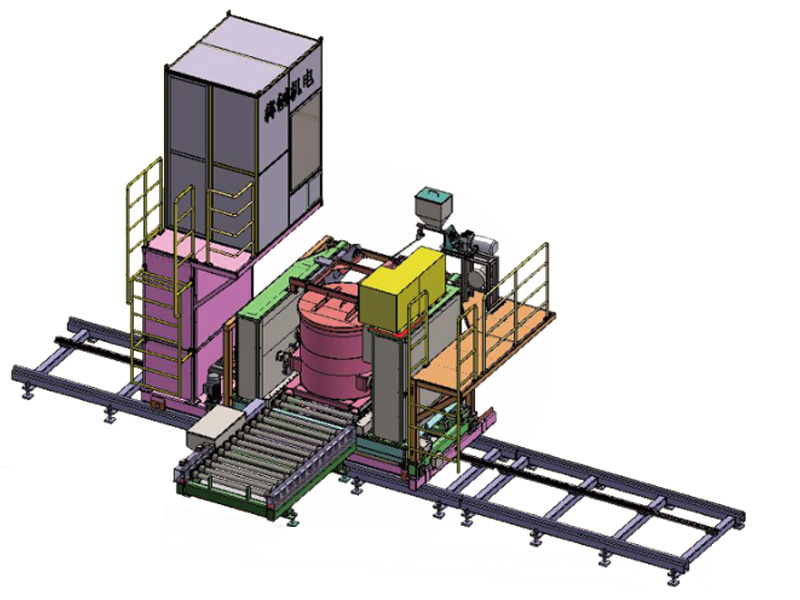

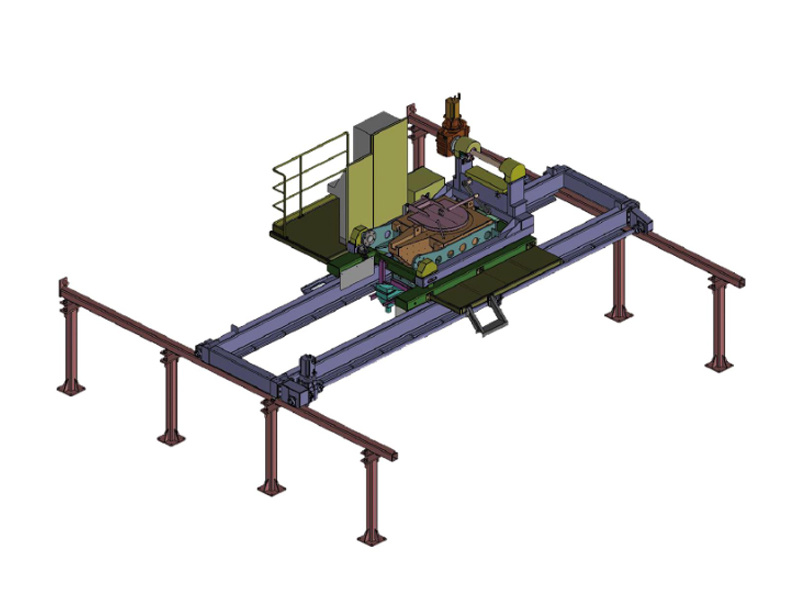

Double-station tilting type automatic casting machine

- Commodity name: Double-station tilting type automatic casting machine

Product Details

Product Introduction

The casting machine adopts electric drive, the whole machine has no hydraulic pressure, no consumables, stable operation and low maintenance cost. It can automatically find the position of pouring or with the modeling line chain co-pouring, automatic quantitative filling of molten iron, to achieve matching modeling production line for fully automated production, especially suitable for vertical modeling line.

The electrical system is controlled by programmable controller, and the longitudinal movement and pouring ladle tilting are all controlled by servo system, which has accurate control and good repetition accuracy. The quantitative determination of molten iron is controlled by electronic weighing system, which is not affected by slag sticking in pouring ladle and the like, and the measurement is accurate. The flow-accompanying inoculation mechanism is adjusted by frequency converter, which is suitable for a wide range of castings.

Product characteristics

● Equipped with 2 pouring bags, both equipped with independent weighing system, independent electric bag cover and independent lateral adjustment mechanism.

● Two sets of ladles can work at the same time, pouring two adjacent sand molds, or they can be used separately.

●The chassis is equipped with a spacing adjustment mechanism, which can electrically adjust the spacing of 2 pouring bags to adapt to different sand mold thicknesses.

● Through ingenious structural design, the height of the turning-over driving part is flush with the pouring ladle, so as to realize barrier-free around the top of the pouring ladle and facilitate the filling of molten iron.

● Using programmable controller with servo system, electronic weighing system, control precision, good repeatability.

● Especially suitable for vertical molding line, 2 sets of casting ladle pouring at the same time, greatly reducing the pouring time.

Main parameters

| Host size | 5mx3.5mx4.2m |

| Track size | 15mx1. 3m |

| Longitudinal stroke | 12m |

| Transverse stroke | 400mm |

| Applicable sand mold thickness range | 150mm-600mm |

| ladle capacity | Larger 1t * 2 |

| Pouring speed | Stepless adjustment |

| Rated power | 15KW |

| Measurement method | Weighing |

Keyword: