Ben Chuang Electromechanical was established in

High Configuration

High efficiency

High precision

Low failure rate

Double-sided compaction function

Cavity external draft function

Energy saving and environmental protection

Wear resistance and long service life

Gentle

Simple structure and easy maintenance

Products

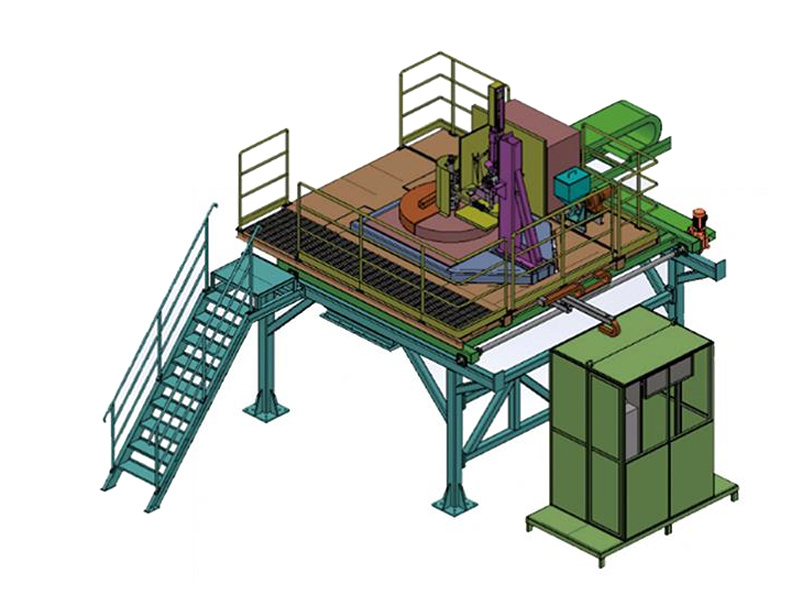

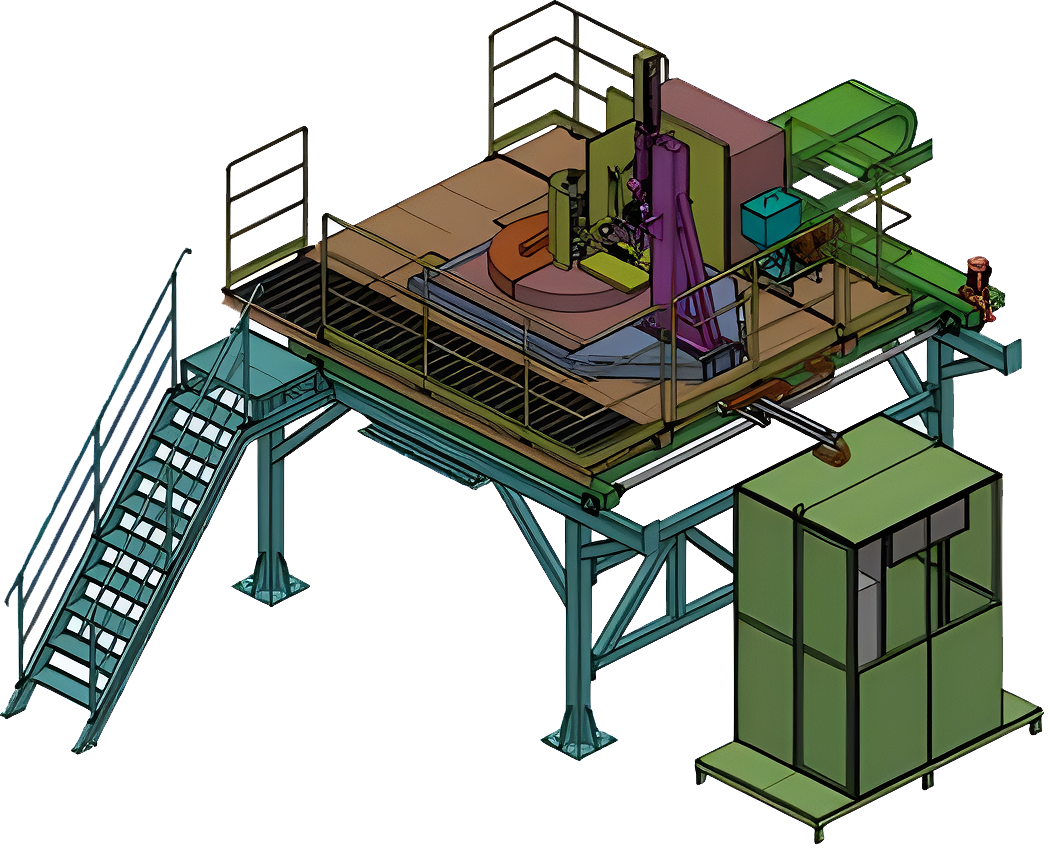

Vertical molding line series: All-electric type, Manhole cover special type, Airtight type, General type, Casting machine series: tilting automatic pouring machine, bottom injection pouring machine.

Video

About Us

Shunping Benchuang Electromechanical Equipment Manufacturing Co., Ltd.

BENChuang Electromechanical Equipment Manufacturing Co., Ltd. Founded in 2016 with a registered capital of 10 million yuan, it is a joint-stock private enterprise integrating scientific research, production and operation.

The company in line with quality, innovation, service purpose. The perfect quality assurance system and after-sales service have been well received by the industry and recognized by the market, and have won the recognition and trust of more and more customers. The company's products are distributed in Shanxi, Hebei, Shandong, Liaoning, Xinjiang, Guangdong, Zhejiang, Yunnan, Jiangxi, Henan, Chongqing, Fujian and Anhui, and more than 400 lines have been delivered to customers by 2023. Products cover the groove pipe fittings, auto parts, motor casing, fire pipe fittings, valves, water pump casing, fitness equipment, power fittings, manhole covers and other major areas.

The company was established in

Registered capital

COOPERATION CUSTOMERS

Technical advantages in the same industry

Modeling speed

The actual production speed of the same model is faster

closed hydraulic circulation system

The pollution of dust in the outside air to the hydraulic oil is avoided, and the stability of the equipment operation is greatly improved.

System Security

In addition to the electrical system is provided with overpressure protection, the hydraulic system of the main pump is provided with overpressure protection (safety overflow). At the same time, the inlet and outlet of the positive plate and reverse plate cylinders are also provided with safety protection valve groups (two-way cross relief valves) respectively. This avoids the possibility of damaging the core components under special circumstances.

Long service life

The positive pressure plate adjustment pad adopts an integrated support structure to improve the service life; the main engine oil tank is welded with stainless steel to improve the service life of hydraulic oil; the main engine hydraulic pump Germany Rexroth has high pressure resistance, low noise and long service life.

Strong after-sales service

After-sales service technical ability, can eliminate on-site problems in a short time, to bring greater benefits to customers.

Short debugging time

The equipment is installed in place and other auxiliary conditions are available to ensure normal production within two days.

Benchuang jidian shehui Zhizao Co. Ltd

Create a new design concept of electromechanical, open the all-electric mode of vertical molding machine, and enter the E era!!!

All-electric type, Manhole cover special type, Airtight type, General type, Casting machine series: tilting automatic pouring machine, bottom injection pouring machine.

News Center

The company's perfect quality assurance system and after-sales service in the industry has been well received by the industry