Contact Information

Tel:+86 15101145231

E-mail:1085557209@qq.com

Add: Economic Development Zone, Shunping County, Baoding City, Hebei Province (North Park)

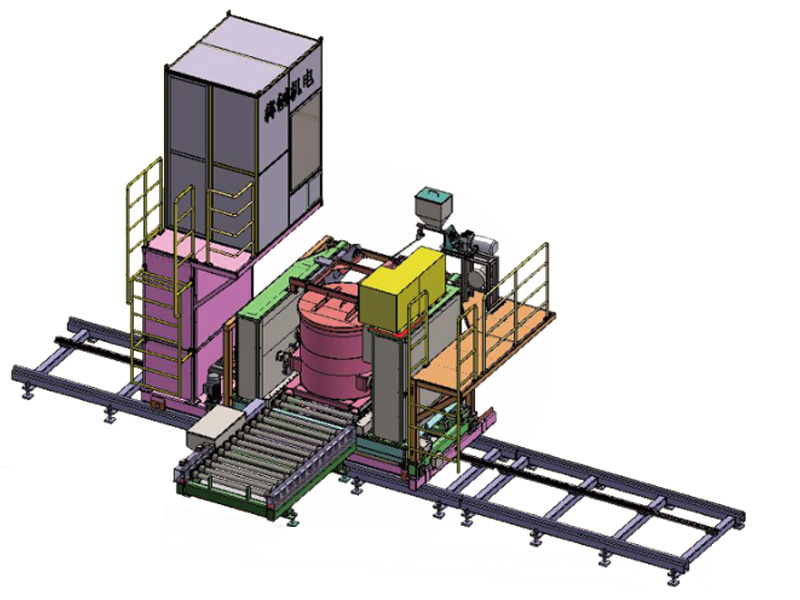

tilting automatic pouring machine

- Commodity name: tilting automatic pouring machine

Product Details

Product overview

The pouring machine has simple structure and reliable performance, can automatically find the pouring or chain with the molding line co-pouring, automatic quantitative filling of molten iron, to achieve matching molding production line for automatic production, suitable for vertical molding line, horizontal molding line and other casting production lines. The whole machine has no hydraulic pressure, and there is no need to use consumables during use, only necessary equipment maintenance is required, and the pouring bag is repaired as appropriate, and the maintenance cost is low.

Function and performance introduction

The casting machine can move longitudinally in the direction of the casting production line and move transversely in the direction of the vertical production line, and the casting ladle can be rotated around a fixed axis. Horizontal movement with ladle rotation, to achieve the molten iron into the sand mold cavity. This machine is equipped with two pouring bags, which can realize alternating pouring and packing. Equipped with flow inoculant adding device, the inoculant can be added quantitatively at the same time of pouring, and the addition amount can be adjusted in a certain range through the system. Equipped with control room, which can isolate molten iron splash and heat radiation and fully protect the personal safety of operators. It is equipped with a manual turning machine. In case of hot bags or other emergencies, the pouring bags can be hoisted to the turning machine and the molten iron can be poured out manually.

The electrical system is controlled by a programmable controller, which is reliable and accurate. Longitudinal movement and ladle rotation, using servo control system, good repeatability. The quantitative measurement of molten iron is controlled by an electronic weighing system, which is not affected by slag sticking in the ladle and is accurate. The addition amount of the flow inoculant is adjusted by the frequency converter, which is suitable for a large range of castings.

Installation and Use Introduction

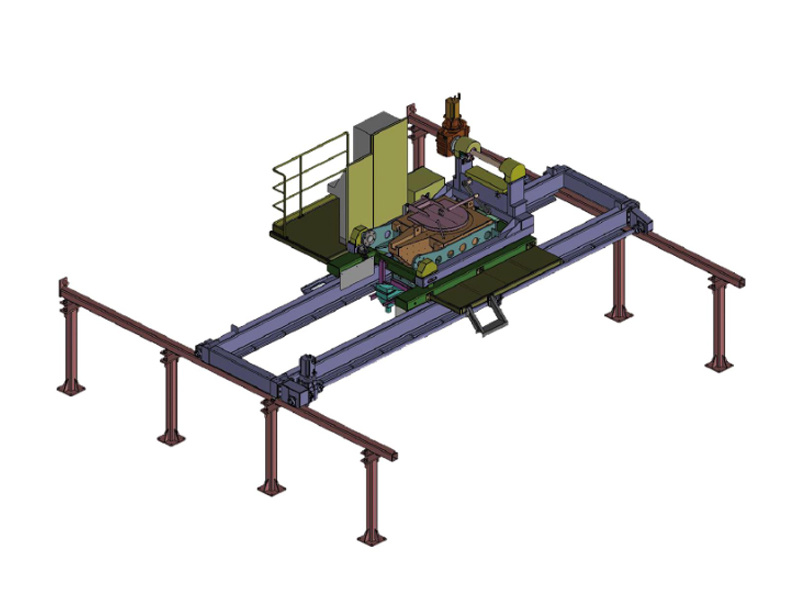

The main body of the casting machine is installed on one side of the casting area of the casting production line, and the track parallel to the production line (provided with the equipment) needs to be laid beside the production line, and the ladle mouth and platform extend to the top of the production line.

When using, it is only necessary to set the weight of each box of molten iron and the thickness of the sand mold before pouring, adjust the position of the pouring ladle and the funnel relative to the sand mold gate, and after the pouring of molten iron is started, the pouring can be automatically found or interlocked with the molding line. During the pouring process, if there is an error between the sand mold gate spacing and the sand mold gate, the longitudinal position of the funnel can be manually adjusted to make the molten iron smoothly injected into the sand mold. At the same time, the pouring speed, molten iron injection amount, inoculant addition amount, etc. can also be adjusted in real time.

Main parameters of equipment

| Host size | 3.7 Mx3.5Mx4.2M (length x width x height) |

| Track size | 12M x 1.7M x 0.95M (customizable) (length x width x height) |

| Weight of whole machine | About 10T |

| Rated power of the whole machine | 10KW |

| Longitudinal travel (parallel to the direction of sand movement) | 8.5M (customizable) |

| Lateral movement stroke (perpendicular to the sand mold movement direction) | 400MM |

| ladle capacity | 600KG/800KG/1000KG/1200KG/1500KG |

| Pouring speed | Stepless adjustment |

| Measurement method | Weighing |

Keyword: