Contact Information

Tel:+86 15101145231

E-mail:1085557209@qq.com

Add: Economic Development Zone, Shunping County, Baoding City, Hebei Province (North Park)

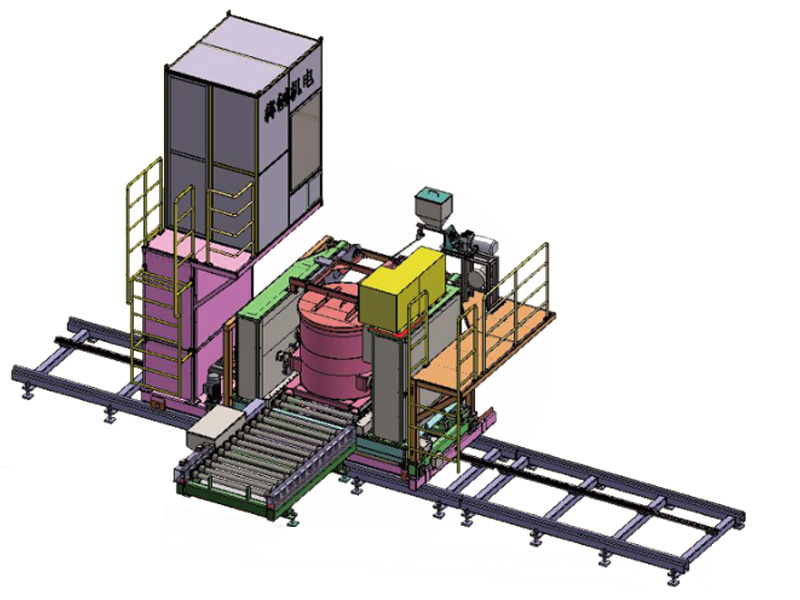

Interchangeable roll-over casting machine

The pouring ladle can enter and leave horizontally to the rear, and the pouring ladle can be removed for iron connection. It can be used with the external track to adopt double-package cross pouring and iron connection to improve production efficiency. Programmable controller is used to control with servo system, electronic weighing system is used to quantify molten iron, and variable frequency flow inoculation system is equipped.

- Commodity name: Interchangeable roll-over casting machine

Product Details

The pouring ladle can enter and leave horizontally to the rear, and the pouring ladle can be removed for iron connection. It can be used with the external track to adopt double-package cross pouring and iron connection to improve production efficiency. Programmable controller is used to control with servo system, electronic weighing system is used to quantify molten iron, and variable frequency flow inoculation system is equipped.

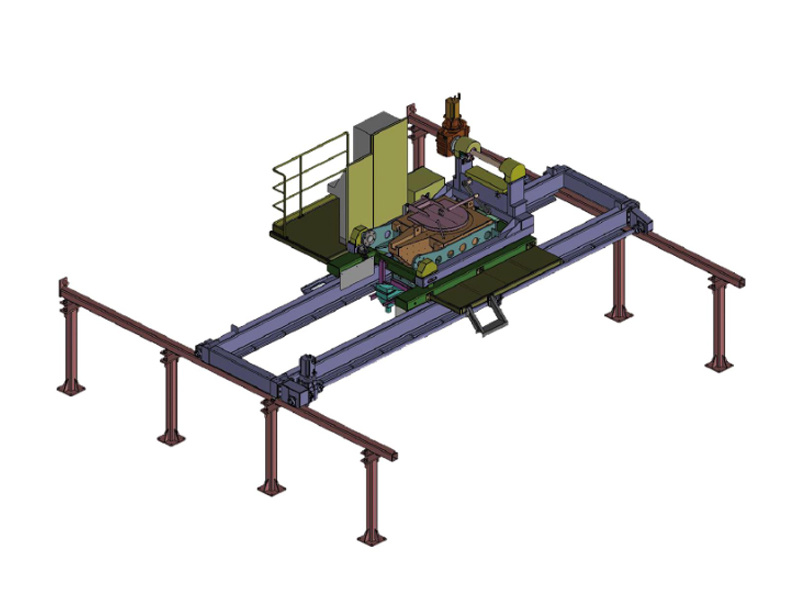

Main technical parameters

| Host size | 4.4mx3mx4.5m |

| Longitudinal stroke | 8m |

| Transverse stroke | 450mm |

| ladle capacity | 1000kg/1500kg |

| Rated power | 10kw |

Keyword: