Contact Information

Tel:+86 15101145231

E-mail:1085557209@qq.com

Add: Economic Development Zone, Shunping County, Baoding City, Hebei Province (North Park)

All-electric type

- Commodity name: All-electric type

Product Details

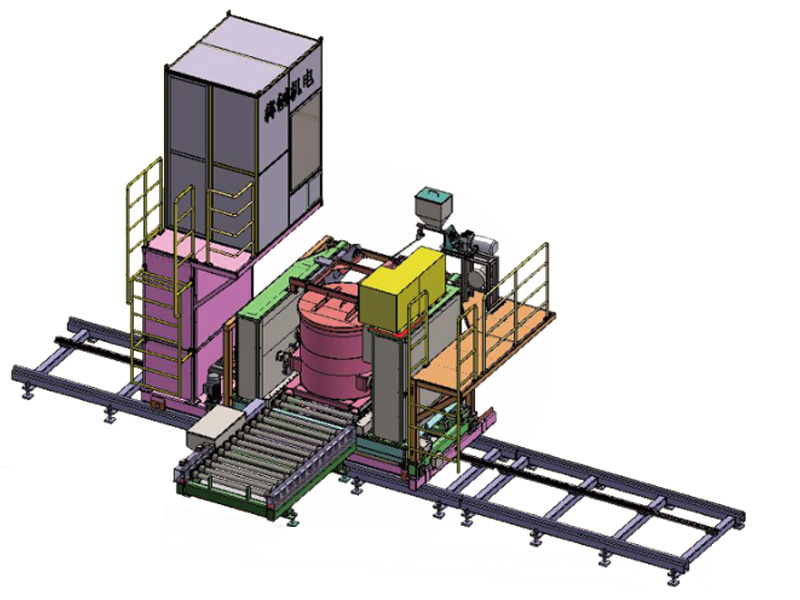

Modeling host

Full servo drive:

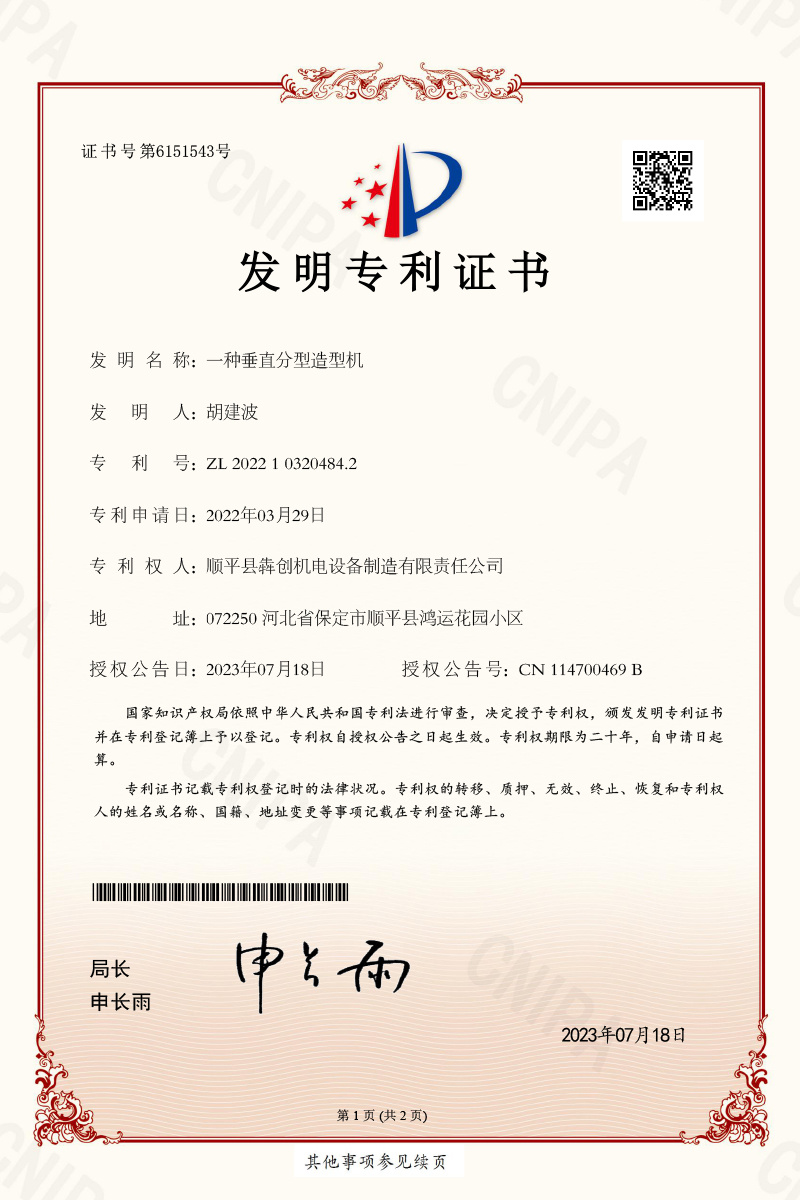

1. Servo drive with invention patent has the following obvious advantages over hydraulic drive (patent type: invention patent; Name of invention: a vertical parting molding machine; Patent number: ZL 2020 1 0320484.2)

Pure electric molding machine has the advantages of hydraulic molding machine, so that the end user can reduce consumption and energy saving in each mold, and virtually reduce the start-up cost. To enable users to improve the boot time, reduce maintenance costs, reduce spare parts consumption, reduce environmental pollution, improve the working environment.

2. The guide rod, wear-resistant base plate and other wear-resistant parts are made of high hardness tungsten carbide surface treatment than the traditional chromium plating life increased by more than 10 times

Host Optional Configuration:1. Fully automatic core lowering machine 2. Type plate quick change unit 3. Dust removal and noise reduction unit 4. Mold hydraulic lock 5. Mold preheating car

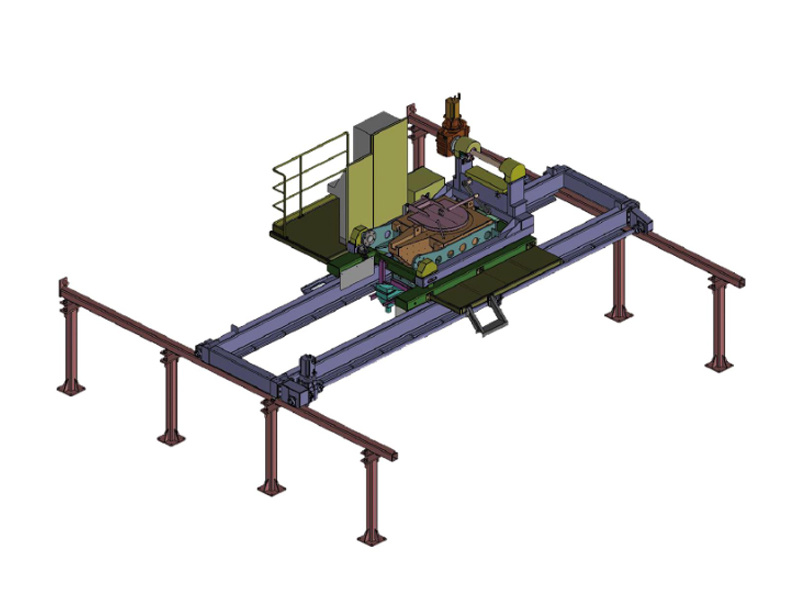

Clamping conveyor

The blessing synchronous machine is composed of three main components such as grid plate platform, splint, U-frame and drive. The standard length is 18 meters. The main function is to realize the transportation and pouring of sand mold. The grid plate platform is equipped with wear strips of 18mm thick, which are ground after heat treatment. The wear strip on the large surface of the splint is made of 12mm stainless steel, the wear strip at the bottom of the splint is made of high chromium quenching and has a thickness of 20mm, a heating pipe is added inside the first 10 splints, and the whole pouring section is provided with a safety protection net.

Clamping conveyor optional configuration:1.21 m clamping and conveying platform 2.10 m double-layer protective splint

Cooling belt conveyor

The belt conveyor is mainly composed of the head component, the middle component, the tail component and the belt.

Main functions:Conveying sand molds and cooling of castings after pouring, length 20 meters to 70 meters optional. Standard dust shield

Product Parameters

| Features | Performance | Servo drive | Hydraulic drive |

| Low power consumption | Standby power | Close to 0 Power | About 30KW |

| Working power | Reasonable output without excess power output | The system has overflow heating, power loss is large | |

| Cooling equipment | None (more energy efficient) | Water cooling or oil cooling (heating power of hydraulic system) | |

| High precision | Accuracy: comparable to CNC machine tools | Accuracy and repeatability of position, velocity and acceleration to 1% mm accuracy level | Accuracy grade: millimeter grade |

| Maintenance-free | Vulnerable parts | Very little | Regularly replace the hydraulic oil, cylinder seal, filter element and other wearing parts |

| Hydraulic oil | None (more environmentally friendly) | Required (periodic replacement) | |

| cylinder system | None (reduce wearing parts or failure rate) | Yes (regular replacement of spare parts) |

| Modeling room parameters | Equipment Model | ||||||||

| 416EV | 417EV | 418EV | |||||||

| A | B | C | B | C | A | B | |||

| Wide | mm | 600 | 650 | 650 | 750 | 750 | 800 | 800 | |

| High | mm | 480 | 535 | 650 | 535 | 600 | 600 | 650 | |

| Thick (optional) | mm | 130-520 | 130-520 | 130-520 | |||||

| Modeling ability | |||||||||

| coreless | Mold | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| with core | Mold | 400 | 400 | 400 | 380 | 380 | 380 | 380 | |

| Conveying length | Meters | 70 | 70 | 60 | 60 | 60 | 50 | 50 | |

| Amount of sand used | ton/hour | 35-40 | 35-40 | 35-40 | 35-40 | 40-45 | 45-60 | 45-60 | |

| Power | Kilowatts | 35 | 35 | 35 | |||||

| Gas consumption | Cubic 1 point | 10 | 10 | 10 | |||||

Certificate

Keyword: