Contact Information

Tel:+86 15101145231

E-mail:1085557209@qq.com

Add: Economic Development Zone, Shunping County, Baoding City, Hebei Province (North Park)

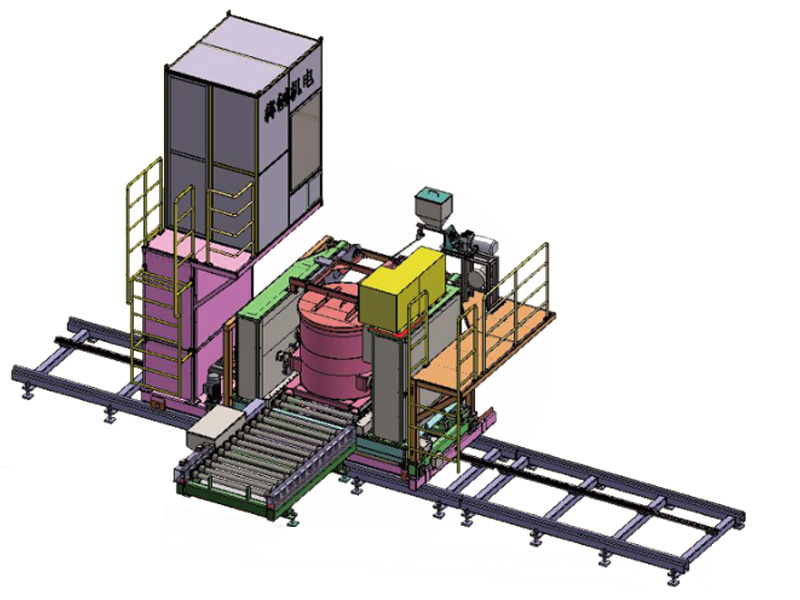

System closed type

- Commodity name: System closed type

Product Details

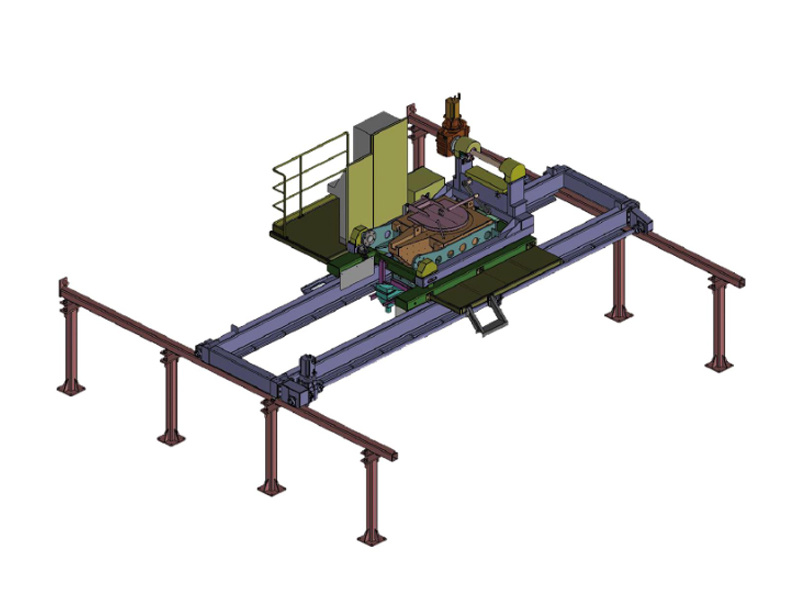

Modeling host

Fully closed hydraulic system:

1. The hydraulic system that has obtained the invention patent is upgraded from the traditional open hydraulic system to a closed hydraulic system, and the respirator that exchanges the oil tank with air is removed. The entire oil tank system adopts a closed structure. Avoid water vapor and tiny particles in the air from entering the hydraulic system. At the same time, the entire hydraulic system is equipped with three sets of high-precision filtration systems, which makes the hydraulic system cleaner as it is used, and the probability of hydraulic system valve stuck and wear is greatly reduced, and the service life of hydraulic oil is greatly improved. improve.

2. The fuel tank system has a nitrogen pressure of about 2BAR, which makes the oil suction of the hydraulic pump smoother and the suction of the hydraulic system empty! The crawling problem was solved.

3. The guide support is changed from 6 to 8 to increase the movement accuracy of the counter plate and reduce the cantilever effect when the counter plate is opened.

4. Oil cylinder, guide rod, wear-resistant floor and other wear-resistant parts are made of high hardness tungsten carbide surface treatment than the traditional chromium plating life increased by more than 10 times

host hydraulic system configuration:Sealed special hydraulic pump (imported), and the selection of a high pressure level of the pump and with feedback valve group, to ensure the speed and accuracy of the system and service life.

Host electrical system configuration:Using the new version of Siemens 1500 control system. It extends the network connection with users to realize remote control, remote diagnosis, remote monitoring, remote data upload and other functions.

Host Optional Configuration:1. Fully automatic core lowering machine 2. Type plate quick change unit 3. Dust removal and noise reduction unit 4. Mold hydraulic lock. 5. Mold preheating car

Clamping conveyor

The blessing synchronous machine is composed of three main components such as grid plate platform, splint, U-frame and drive. The standard length is 18 meters. The main function is to realize the transportation and pouring of sand mold. The grid plate platform is equipped with wear strips of 12mm thick stainless steel. The wear strip on the large surface of the splint is made of 5mm stainless steel, and the wear strip on the bottom of the splint is made of 45# steel with a quenching thickness of 20mm.

Clamping conveyor optional configuration:1.21 m clamping and conveying platform 2.10 m double-layer protective splint 3. Clamping machine guard net

Cooling belt conveyor

The belt conveyor is mainly composed of the head component, the middle component, the tail component and the belt.

Main functions:Conveying sand molds and cooling of castings after pouring, length 20 m to 70 m optional

Optional configuration:Dust shield

Product Parameters

| Modeling room parameters | Equipment Model | ||||||||

| 416 | 417 | 418 | |||||||

| A | B | C | B | C | A | B | |||

| Wide | mm | 600 | 650 | 650 | 750 | 750 | 800 | 800 | |

| High | mm | 480 | 535 | 650 | 535 | 600 | 600 | 650 | |

| Thick (optional) | mm | 130-520 | 130-520 | 130-520 | |||||

| Modeling ability | |||||||||

| coreless | Mold | 500 | 500 | 480 | 480 | 480 | 450 | 450 | |

| with core | Mold | 420 | 420 | 400 | 400 | 400 | 370 | 370 | |

| Conveying length | Meters | 70 | 70 | 60 | 60 | 60 | 50 | 50 | |

| Amount of sand used | ton/hour | 35-40 | 35-40 | 35-40 | 35-40 | 40-45 | 45-60 | 45-60 | |

| Power | Kilowatts | 75 | 75 | 75 | |||||

| Gas consumption | Cubic 1 point | 10 | 10 | 10 | |||||

Keyword: