Contact Information

Tel:+86 15101145231

E-mail:1085557209@qq.com

Add: Economic Development Zone, Shunping County, Baoding City, Hebei Province (North Park)

Manhole cover special type

- Commodity name: Manhole cover special type

Product Details

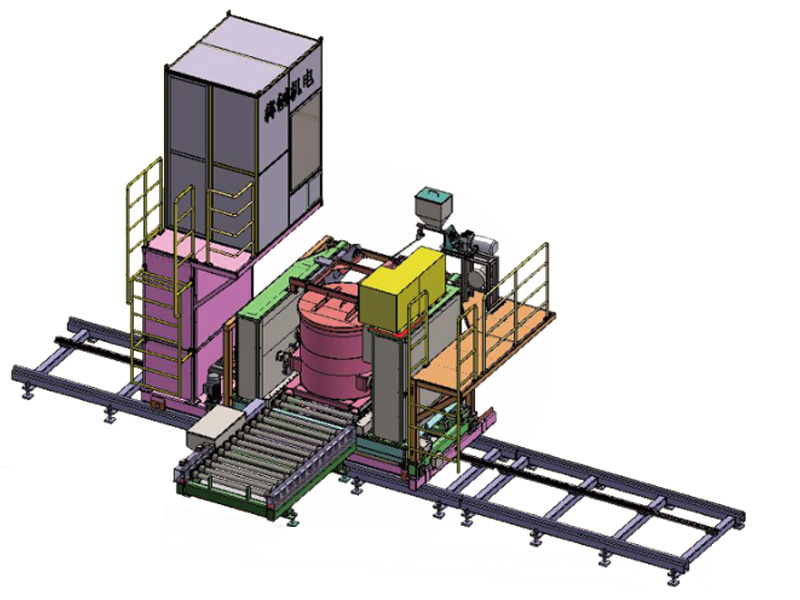

Modeling host

host hydraulic system configuration:Constant force hydraulic pump, hydraulic valve (Germany Rexroth) imported, and the selection of the valve group with feedback, to ensure the speed and accuracy of the system and service life.

Host electrical system configuration:Using the new version of Siemens 1500 control system. It extends the network connection with users to realize remote control, remote diagnosis, remote monitoring, remote data upload and other functions.

Host Optional Configuration:1. Fully automatic core lowering machine 2. Type plate quick change unit 3. Dust removal and noise reduction unit 4. Mold hydraulic lock.

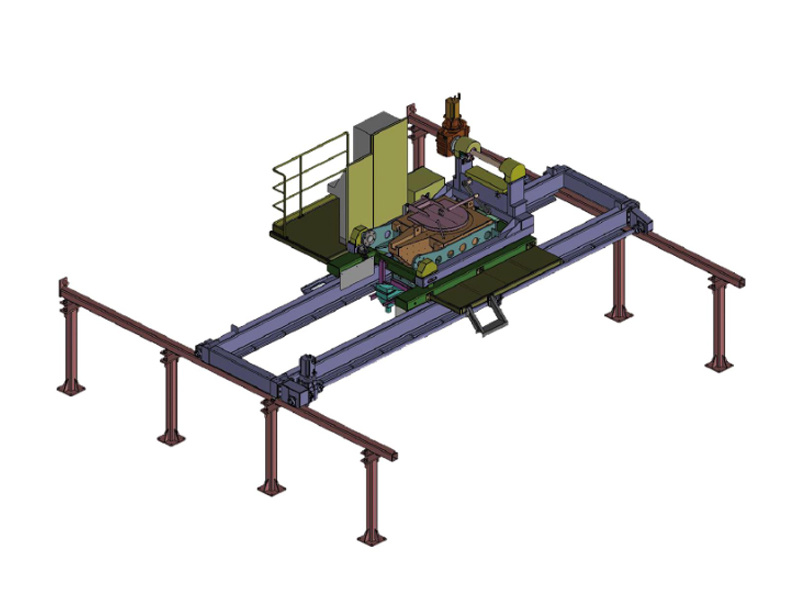

Holding conveyor

The holding conveyor is composed of moving platform, static platform and main components of driving device, with a standard length of 18 meters. The main function is to realize the transportation and pouring of sand mold. The dynamic and static platform rises alternately and the moving platform moves back and forth to realize the transportation of sand mold.

The dynamic and static platforms are respectively equipped with 30 thick wear-resistant slideways.

Optional configuration of holding conveyor

1.12 m double-layer cast protective splint on both sides

Cooling belt conveyor

The belt conveyor is mainly composed of the middle component of the head component, the tail component and the belt.

Main functions:Conveying sand molds and cooling of castings after pouring, length 20 meters to 40 meters optional.

Optional configuration:Dust shield

Product Parameters

| Modeling room parameters | Equipment Model | |||||||||

| 419 | 4110 | 4111 | ||||||||

| A | B | C | A | B | C | A | B | |||

| Wide | mm | 900 | 950 | 900 | 1000 | 1000 | 1050 | 1100 | 1100 | |

| High | mm | 650 | 700 | 900 | 900 | 950 | 1000 | 1050 | 1100 | |

| Thick (optional) | mm | 150-500 | 150-500 | 150-500 | ||||||

| Modeling ability | ||||||||||

| coreless | Mold | 350 | 350 | 250 | 250 | 250 | 250 | 250 | 250 | |

| with core | Mold | 250 | 250 | 150 | 150 | 150 | 150 | 150 | 150 | |

| Conveying length | Meters | 40 | 40 | 40 | 35 | 35 | 35 | 30 | 30 | |

| Amount of sand used | ton/hour | 45-50 | 45-50 | 50-60 | 60-80 | 60-80 | 60-80 | 80-90 | 80-90 | |

| Power | Kilowatts | 100 | 120 | 120 | ||||||

| Gas consumption | Cubic 1 point | 10 | 15 | 15 | ||||||

| Modeling room parameters | Equipment Model | |||||||||

| 4112 | 4113 | 4114 | ||||||||

| Wide | mm | 1200 | 1300 | 1400 | ||||||

| High | mm | 1100 | 1200 | 1300 | ||||||

| Thick (optional) | mm | 150-500 | 150-500 | 180-550 | ||||||

| Modeling ability | ||||||||||

| coreless | Mold | 200 | 180 | 150 | ||||||

| with core | Mold | 150 | 150 | 100 | ||||||

| Conveying length | Meters | 30 | 25 | 25 | ||||||

| Amount of sand used | ton/hour | 90-120 | 90-120 | 90-120 | ||||||

| Power | Kilowatts | 120 | 120 | 150 | ||||||

| Gas consumption | Cubic 1 point | 15 | 15 | 15 | ||||||

Keyword: