Contact Information

Tel:+86 15101145231

E-mail:1085557209@qq.com

Add: Economic Development Zone, Shunping County, Baoding City, Hebei Province (North Park)

Bottom injection type casting machine

- Commodity name: Bottom injection type casting machine

Product Details

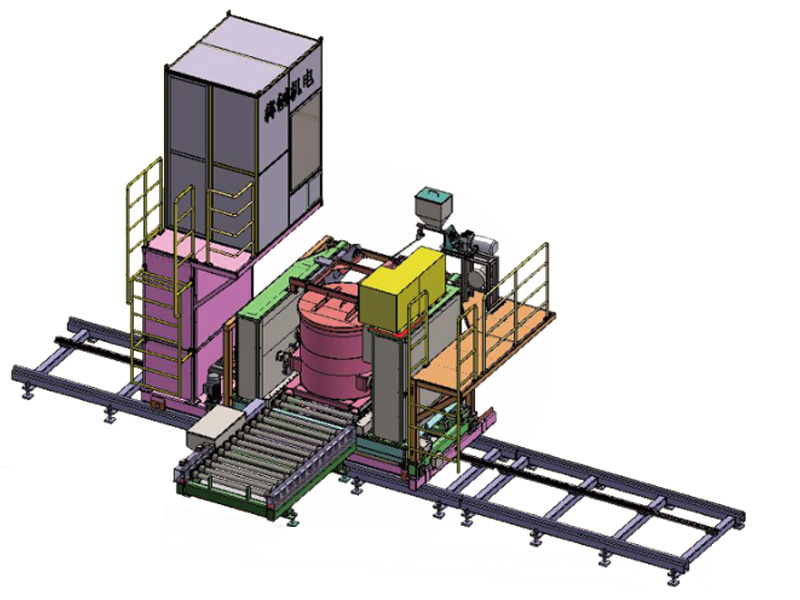

Thermal insulation type

Product characteristics

● The whole machine has no hydraulic pressure, and the main power parts are all electric, so as to eliminate the potential safety hazards caused by hydraulic leakage, pipeline heating or molten iron splash.

●It is controlled by programmable controller, with manual and semi-automatic modes. In semi-automatic mode, the pouring liquid flow is controlled by the teaching program and is automatically completed by interlocking with the molding line.

● The plug rod device adopts servo electric cylinder, which is flexible and precise in control.

● The plug rod device has adjustable height, pneumatic grinding, horizontal anti-deviation, plug rod quick clamp, etc. The flow inoculation is controlled by a frequency converter, and the addition amount is steplessly adjustable.

●The pouring package is of cylindrical structure, with internal masonry refractory materials and equipped with medium frequency electric furnace heating to maintain the temperature of molten iron.

Main parameters

| Host size | 4.2mx3.8mx4.7m |

| Longitudinal stroke | 900mm |

| Transverse stroke | 1100mm |

| ladle capacity | 1000kg/1500kg/2000kg |

| Rated power | 5kW (excluding medium frequency electric furnace) |

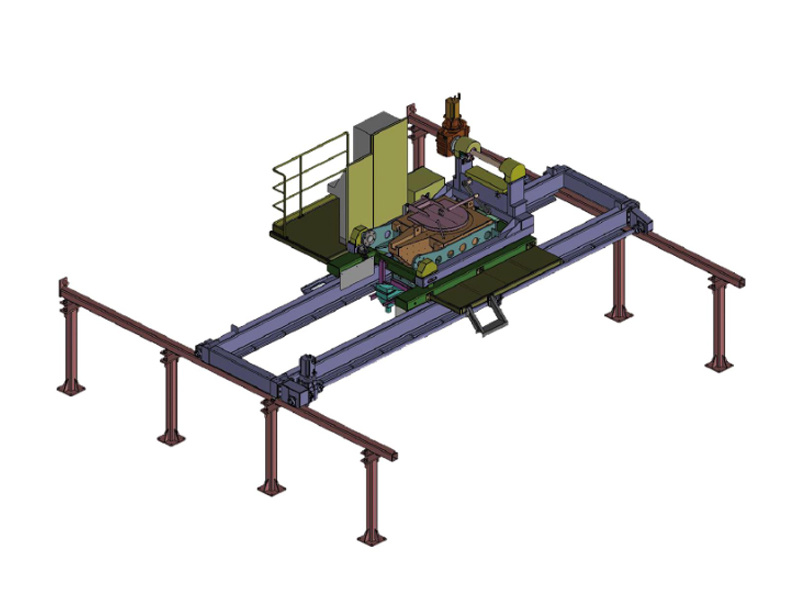

Non-insulated

The pouring bag is long wedge-shaped, with internal masonry refractory materials, equipped with a turnover mechanism to facilitate the discharge of molten iron, and can be installed with ground rails to extend the pouring range.

Main parameters

| Host size | 3.8mx5mx5.2m |

| Longitudinal stroke | 1250mm |

| Transverse stroke | According to the track |

| ladle capacity | 1000kg/1500kg/2000kg |

| Rated power | 5kW |

Keyword: